Rust can destroy the beauty of your prized car, or ruin a perfectly fine set of wrought-iron patio furniture. While metal is a tough material that generally lasts decades, rust is one of the few things that can make that strength wane over the course of weeks or months.

Although the list of things that encourage rust is long, one of the most common issues is dirt. This can come from dust, a lack of care during the metalworking process, or even from cleanings. Rust prevention starts long before the finished product ends up in the customer’s hands, and is an ongoing process that has to be done carefully and with due diligence.

You may have been unfortunate enough to purchase something metal, only to find it rusted within a short time after owning it. The problem of pre-existing rust is certainly one that could be to blame for your misfortune.

Handling pre-existing rust

Pre-existing rust takes root when manufacturers don’t thoroughly clean the metal before adding a rust inhibitor. Once the pieces are coated, stored, and finally shipped, this microscopic rust has already had the chance to begin damaging the metal.

This microscopic rust could be the result of incoming materials or something that was initiated in previous metalworking processes while with the manufacturer. The only true way to deal with pre-existing rust is for manufacturers to institute better in-process corrosion inhibition and for companies to improve quality assurance protocols on receivables.

Not to worry—if you’ve purchased or been shipped metal you believe may have come with traces of rust already present, there are steps you can take to minimize rust growth and hopefully prevent future damage.

Preventing rust caused by dirt

Since dirt is such a common contributor to rust, it’s important to understand how dirt can influence rust prevention and how you can stop it from encouraging future rust growth.

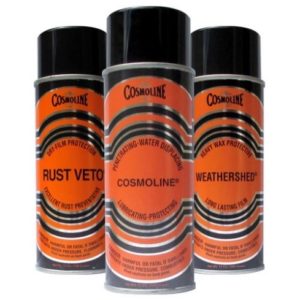

- Develop a clean and rinse stage before adding any kind of rust inhibitor. Using something like Cosmoline before properly cleaning, rinsing, and drying the metal will only trap dirt beneath the inhibitor.

- Thoroughly clean all parts, making sure to inspect gaps, creases, and crevices that might trap dirt.

- Inspect rust prevention application tanks for dirt load. By cleaning and rinsing this tank, you can prevent dirt from getting into the inhibitor and sneaking onto your parts.

Wet parts and rust

Wet parts and rust

Water contamination, humidity, and other fluids can all contribute to rust. Likewise, too much inhibitor or mixing two or more can create a form of streaky corrosion. If you have rust caused by wet parts, you have some options.

- Use a water-displacing and separating rust inhibitor with agitation to get a clean, full coating of rust preventive on your parts, like the Cosmoline aerosol.

- Make sure to clean and dry parts completely.

- Use inhibitors with a stronger-than-average film strength to ensure optimal coat durability.

Avoiding rust preventive abuse

If you’re using a rust preventive, that’s great—but overuse or a poor preventive can do more harm than good for your metal. Using the same inhibitor over time can cause it to lose effectiveness. The effectiveness can be influenced by factors such as:

- High water hardness

- Low pH level

- Low concentration

- Excessive water contamination or high dirt load

- Poor agitation

To get the most protection out of your preventive, check your product for any of the parameters outlined above. These factors contribute to a weak rust inhibitor. Learning to practice better fluid maintenance and establishing ‘dump and recharge’ cycles can lead to more effective use of a preventive without wasting product or encouraging rust to grow on your metal.

To get the most protection out of your preventive, check your product for any of the parameters outlined above. These factors contribute to a weak rust inhibitor. Learning to practice better fluid maintenance and establishing ‘dump and recharge’ cycles can lead to more effective use of a preventive without wasting product or encouraging rust to grow on your metal.

Improper application of preventive

Poor application can render an effective preventive completely useless against rust. When a rust inhibitor isn’t properly applied, the coverage won’t be adequate and rust can form. Whether you don’t give the coating enough time to dry or you didn’t coat the entire surface, you can do the following:

- Give each coating the recommended time to dry before adding addition coats or handling.

- Dip or spray inhibitors are optimal for effective coverage. Avoid brush and paint type applications.

- Ensure parts are completely dry and free of dirt before applying preventive.

Rust prevention is an on-going effort

To truly beat rust, you have to be proactive in your treatment, and aware under what conditions rust can form. It’s important to know that the metalworking process isn’t perfect and that even if you’re prepared to do everything possible to prevent rust, the problem could start with manufacturers or the packaging process.